FREQUENTLY ASKED QUESTIONS

We specialize in researching how to make industrial cooling water systems more energy-efficient and power-saving. To achieve this goal, we optimize system architecture design, explore every potential dimension for energy savings, and strive for continuous innovation.

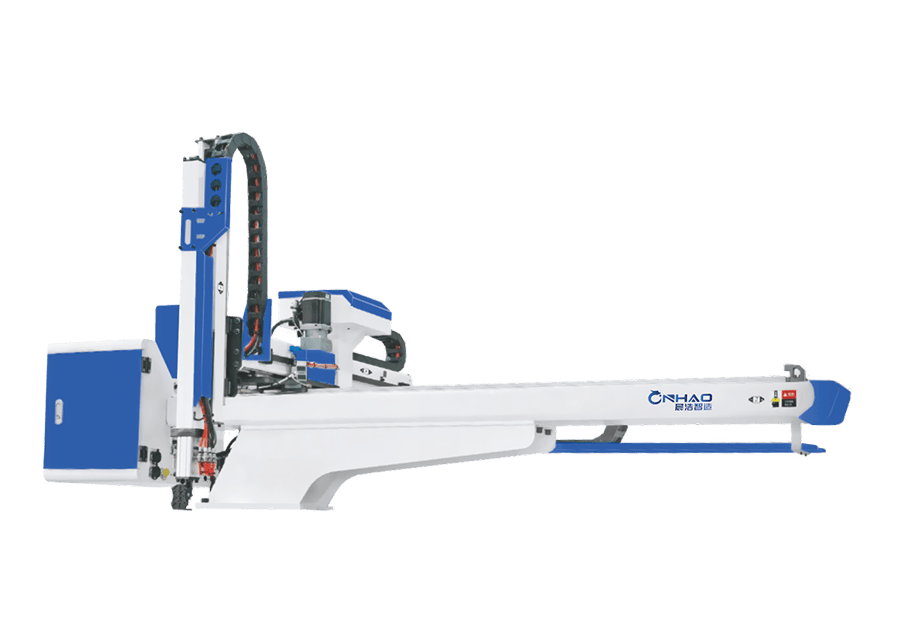

We are a source factory specializing in turnkey planning for injection molding workshops, dedicated to helping enterprises achieve cost reduction and efficiency improvement in their production. From workshop layout design and injection molding equipment selection to process optimization and management enhancement, we provide end-to-end solutions to maximize your factory’s productivity and profitability.

Compared to traditional water, electricity, and gas systems—where pipelines, cables, and ducts were simply installed without optimized layout (often messy and inefficient)—modern smart utility systems feature streamlined, scientific designs that are neat, functional, and energy-efficient. More importantly, intelligent planning reduces energy waste, helping businesses achieve green and sustainable development.

Never opt for traditional decentralized feeding systems—they consume excessive energy and make pipeline maintenance a nightmare. Our Smart Central Feeding System features:

✅ Industrial-grade modular design – Reduces energy consumption by 30%

✅ Real-time material monitoring – Access data anytime via your smartphone

✅ 15 years of expertise – Specialized in plastic injection molding solutions

CONTACT US FOR ANY QUESTIONS

Tel. +86-574-62553803

Email. marketing@slecotech.com

Add. #5,Zhishengyungu North Area, No.818 North Xinjian Road, Yuyao,ZheJiang,China